Have you ever thought about using light-emitting diodes (LEDs) in your cultivation room? If so, you are certainly not the only one! LEDs have come a long way from their origins as the indicator lights found in the display panels of electronic equipment. Nowadays they are popping up everywhere as they become cheaper to produce. There are LED garden lights and there is LED home lighting, and recently of course, LED grow lights too.

Some growers believe that it’s not a question of if LEDs will become the most common supplementary light source for plants, but when. The major questions for most growers are whether LED grow lights are actually effective, and to what extent they can be used in the same way as traditional grow lights. In order to answer these questions, an understanding of the practical use of LED grow lights is required. This article will give you some insight into the practical aspects of using LEDs and reveal some of the pros and cons. First, however, we will explain the principles of LED lighting so that we can understand how to use it.

What are LEDs?

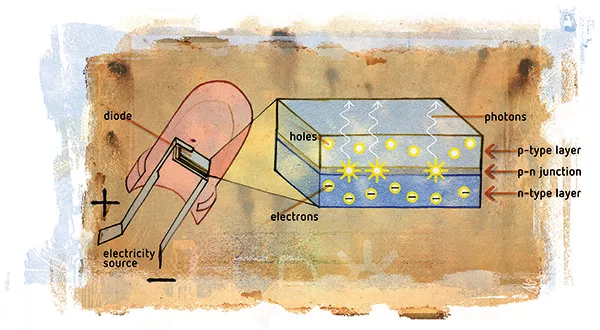

All LEDs are semi-conductors that produce light by a process called electro-luminescence. LEDs are made out of two types of material, the N-type and P-type. The N-type consists of negatively charged free electrons and the P-type has positively charged gaps ('holes'). When the N-type layer is connected to the negative (-) end of an electrical circuit and the P-type to the positive (+) end of the circuit, the free electrons can move in an electrical flow. The free electrons are attracted to the positive holes in the P-type material. However the hole has less energy than the electrons. In order to 'fit' into the hole the electron has to release some of its energy. In the case of LEDs this energy is emitted in the form of a photon, which is light. The intensity of the light emitted from an LED depends on the energy released by the electrons jumping into the positive hole (figure 1).

The color emitted by the light photons depends on the semi-conductive material in the LED. LEDs can be manufactured in such a way that the photon colors will match the light-absorbance peaks of important plant pigments, such as the red and far-red-absorbing forms of phytochrome, or the red and blue peaks of leaf photosynthetic action spectra. This basically means that LED lighting can save energy by producing only the colors that are essential for plant growth and development.

That’s the technical part for now… But how does all this relate to your beloved plants? And how can you choose the right LED grow light?

LEDs for crop production and some practical units

As we already know from the other research article, plants use light for photosynthesis and development. Light for photosynthesis is described by the PAR (photosynthetic active radiation) or PPFD (photosynthetic photon flux density). That is the amount of light, between 400 and 700 nm, used for photosynthesis. For normal cultivation purposes a minimum of 50 to 200 µmol/m2/s is required, but this obviously depends on the type of plants and how much light they require. As a rule of thumb, the more light you provide, the better the plants will grow. However, there is a point beyond which they are unable to make further use of extra light: around 500 µmol/m2/s.

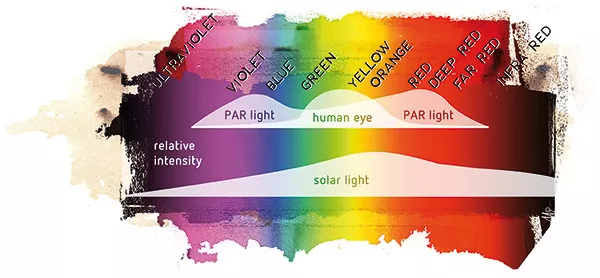

When you are choosing an LED light sources, it is important to keep in mind that plants have different light absorption peaks to the human eye. Photosynthetic light has absorption peaks in the blue and red light spectra, while humans have their light peak in the yellow/green spectra (see figure 2). This means that photosynthetic light is certainly not the same as lux or lumen, which is the 'human measure of brightness'. When you are assessing an LED grow lamp, you will need to know its specification for photosynthetic light production in PAR or PPFD. Unfortunately, these light specifications are not always available for all LED grow lamps.

PAR and lux are different physical quantities (see figure 2), there is not a clear one-to-one relationship between PAR and lux. Basic conversion factors have been formulated for different light sources and corresponding light spectra, so that a different conversion factor will apply for different light sources (Table 1).

But what about LED conversion factors? Basically, LEDs are different from other light sources because they can have very different spectral compositions, meaning that an all-purpose conversion factor is not possible.

Table 1. Conversion factors for different light sources from lux (lumen/m2) to PAR (µmol/m2/s)

| Light source | Type | 400 - 700 nm1 | 400 - 800 nm2 |

|---|---|---|---|

| Incandescent | 3,000K | 0.019 | 0.036 |

| High pressure sodium | 0.012 | 0.013 | |

| Mercury | Clear | 0.011 | 0.012 |

| Phosphor-coated | 0.013 | 0.014 | |

| Metal Halide | 0.014 | 0.015 | |

| Fluorescent | Cool white | 0.013 | 0.013 |

| Day light | 0.014 | 0.015 | |

| GRO | 0.029 | 0.030 | |

| GRO/WS | 0.019 | 0.022 | |

| CWX | 0.016 | 0.018 | |

| Clear day (sun and sky) | 6,000K | 0.018 | 0.024 |

| North skylight | 12,000K | 0.020 | 0.024 |

1. Light spectrum for photosynthesis

2. Photosynthesis and additional far-red light (700 – 800 nm) used for plant development

Evaluating an LED grow lamp

However, it is still possible to determine the quality of an LED grow lamp without profound technical knowledge.

All the LED lighting systems sold on the market as 'grow lights' are made up of different combinations of LEDs. They can consist of up to ten different types of LEDs. Each individual LED should consume at least one watt of power to be effective for plant lighting; below this level, the light emitted will not have enough penetrative power to illuminate the whole plant properly. But there is more to it than that. When evaluating an LED lamp, you should look for high intensity or high brightness 1W LEDs, which measure 10mm and are of the current generation.

In most conventional lamps, the greater the electric power they consume, the higher both the total lumens emitted and the lumens per watt. However, this does not apply to LED lamps. At higher input power levels, each individual LED will certainly be brighter, but they are less efficient (they will emit fewer lumens per watt). There is also no effective difference in penetrative power for horticultural purposes between a 1W LED and a 3W LED. This is a fundamental difference between traditional grow light systems and LED-based systems. A circuit containing 90 x 1W LEDs will be more powerful and more efficient than one containing 30 x 3W LEDs: you cannot simply compare the total wattage in the same way you are used to doing with discharge light systems.

There is another factor to take into account: it is not uncommon that a 3W LED, for example, will be limited to between 2.2W and 2.8W. It is important to study the optimum luminous efficiency, heat loss and life span of each diode. Be aware that LED lamps will also need power to run the LED drivers, fans for cooling and for heat loss. For example, a 135W LED unit will, in reality, only provide about 110 watts of light energy.

Numerous configurations exist for LED grow light systems, such as UFO grow lights, grow light panels and single spot lamps. You should be looking for a system with a minimum power of 90 watts, depending on your specific requirements and situation of course.

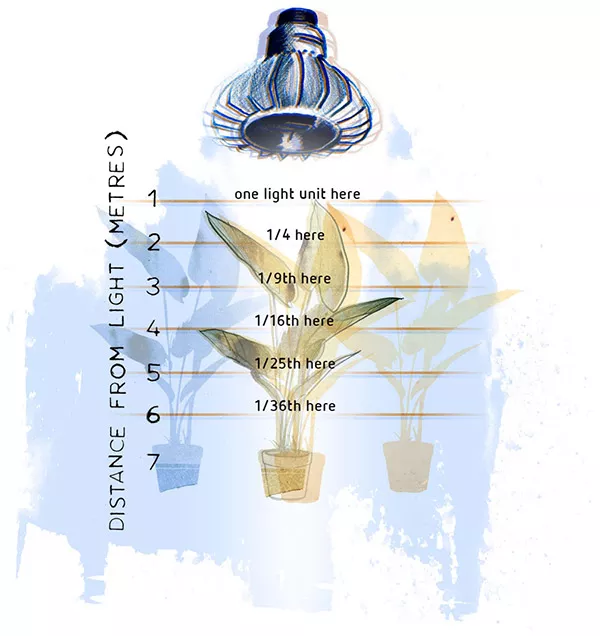

A practical difficulty is that (LED) light is governed by the inverse square law: when the distance from a light source is doubled, the amount of light received falls not by 2, but by 2 squared – i.e. by a factor of 4 (figure 3).

The potential of LED grow lamps

One of the most important benefits of LED lights are their energy-efficiency since they produce less unnecessary light photons and heat! The heat produced from incandescent and discharge lights, although it may be beneficial to plants, is not economical. Table 2 shows that LEDs require only 25% of the power of an incandescent lamp to produce the same amount of light (in lumen). This gives LEDs a substantial economic advantage over traditional light bulbs.

Table 2. Electrical efficiency of different light sources based on equal light production.

| Lumens produced | Watts required for an incandescent lamp | Watts required for a compact fluorescent lamp (CFL) | Watts required for a LED lamp |

|---|---|---|---|

| 400 - 500 | 40 | 8 - 12 | 6 - 9 |

| 650 - 900 | 60 | 13 - 18 | 8 - 12.5 |

| 1,100 - 1750 | 75 - 100 | 18 - 22 | 13+ |

| 1,800+ | 100 | 23 - 30 | 16 - 20 |

| 2,800 | 150 | 30 - 55 | 25 - 28 |

When comparing LEDs to the most common source for plant lighting, high-pressure sodium (HPS), it is generally recognized that the newest LEDs are more energy-efficient. High-pressure sodium lamps (HPS) produce 1.8 µmol of light for each Joule of energy input, while the latest LEDs produce 2.3 µmol light per Joule consumed.

Furthermore, LEDs produce less waste heat, so lamps can be placed much closer to crop surfaces without the risk of overheating and heat stress for the plants. By contrast, high-intensity discharge (HID) lamps require considerable a separation between lamps and plants to ensure uniform light distribution as well as to avoid heat stress from the lamps. This means that LED systems can be designed much more flexibly – horizontal, vertical or inter-crop lighting are all possible, for example. LEDs are also more suitable in multi-layer plant systems.

Another major advantage is that LEDs are more robust and long-lived than traditional light sources with filaments, electrodes, or gas-filled, pressurized lamp enclosures. LEDs also have instant restrike capabilities and do not need time to warm up to achieve full brightness.

Still some hurdles…

These advantages make LEDs an interesting alternative to the current lighting systems used to grow plants, such as HPS and metal-halide (MH). LEDs, however, have not yet achieved broad acceptance as a horticultural light source. LED lights require a higher investment at the outset, and LED bulbs often cost more than the fixtures into which they are placed. This expense can make growers hesitate. Luckily, the evolution of the LED has been very favourable: each decade, LED prices have decreased by a factor of 10, while performance has increased by a factor of 20. The future mass production of LED lighting will probably also reduce the cost of building LED lighting and hopefully the selling price.

One important drawback these days is the difficult interaction of LEDs with respect to plant growth. Some growers have experienced reduced production or lack of development in plants grown with LED, compared to traditional light sources. Indeed several studies have highlighted decreased yield or plant development due to LED lighting. A possible misunderstanding and thus miscalculation is the effect of the heat produced. More heat, for example produced by HPS or MH lamps, significantly improves plant growth. When comparing these plants to 'LED plants', which usually lack the additional heat, it is often clear that the HPS or MH plants grow better than LED plants.

It is important to remember that when it comes to the light spectrum, red or blue/red light combinations only are not good enough. Many first generation LED grow lamps were bi-band (just red and blue) which proved to be inadequate for most plants. Although these two wavelengths would be sufficient for light energy fixation (photosynthesis), most plants still require limited amounts of light from other portions of the spectrum. To ensure that multiple plant processes are stimulated as effectively as possible, broad photosynthetic light spectra (comparable to the sunlight) are preferable.

Most producers of LED grow lamps consider the exact light spectrum used as a trade secret. They usually cite a more general ‘color composition’, called the color temperature. Basically a color temperature between 2,700K (2,700 Kelvin, warm white) and 6,500K (cool white) is usable for plant production. Keep in mind that a 'cooler' and more bluish color may have an inhibitory effect on flowering or flower induction!

For now, a lot more research and awareness are still needed to determine the optimum light spectra and thus LED lamps for specific plants or cultivation purposes. Since LED systems have not yet been optimized, as HPS or MH lights have been, these remain the best light sources to grow your plants with.

LED grow lights – the verdict

So, are LED grow lights just another fleeting fashion or are they really worth a try? They certainly work for plant cultivation, but you should be critical when evaluating a potential 'LED grow lamp'. If you’re considering a new LED lamp, you should look first at its LED components, photosynthetic light, light spectra and power consumption.

Remember that:

- A minimum of 90W is recommended for plant lighting

- Individual LEDs should at least be 1W or more, preferably 10 mm and the latest generation

- Look for high-intensity or high-brightness LEDs

- Contrary to what you might expect, a higher input power makes an LED less efficient (so 3x 1W is more efficient than 1x 3W)

- Doubling the distance between the lamp and the plant will reduce the light by 4 (22)

- Achieve photosynthetic light illumination from 50 – 200 µmol/m2/s till 500 µmol/m2/s for most plants

- Choose a broad light spectrum (3 or 5 band) with some red and far-red light for flowering

- When plant production specifications are missing, try to aim at: A color temperature between 2,700K and 6,500K

The techniques for using LEDs in plant production have not yet been perfected as with existing common forms of plant lighting. Better knowledge of what plants need and how LED lights work will probably lead to the widespread adoption of the LED as a plant lighting source. It certainly seems that the future for LEDs is bright!