Heading into September, the light has started to change and fall feels right around the corner. The quantity and quality of light clearly is huge on plant production. Let's walk through some of the key light considerations for your grow so we can make the most of every season and photoperiod.

Light quality and intensity

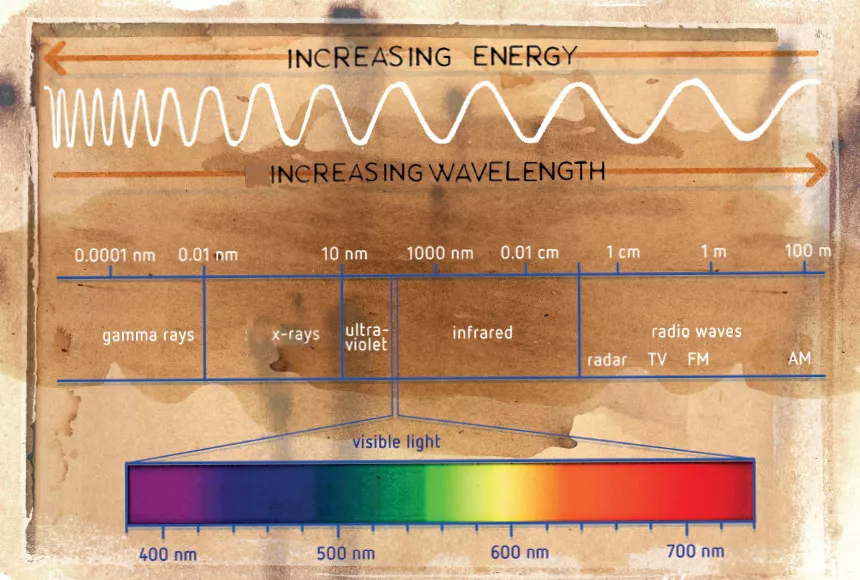

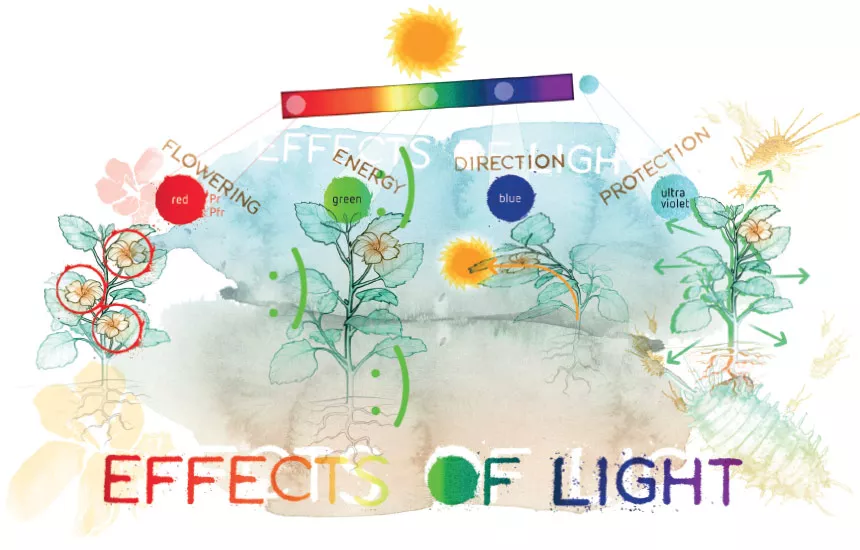

Visible light is defined as a type of electromagnetic radiation and has a wavelength in the 400-700 nanometers (nm) range, which represents the rainbow spectrum of colors. Plants absorb visible light, better known in the industry as photosynthetically active radiation (PAR). Plants also make use of some UV-light, which is less than 400 nm and just outside the visible spectrum.

Light travels in waveform and imparts energy on surfaces as if it were in particle form. Visible light is absorbed as photons, which represent a quanta of light. The amount of photons hitting a surface area over time is known as light intensity and measured as photosynthetic photon flux density (PPFD). So, plants not only need the right light (PAR) to grow, they also need a minimum intensity of it.

Plants each have a light saturation point, which determines their threshold level above which greater intensity does not bring greater plant production. A plant's light saturation point depends on its developmental stage, species, and management techniques. Generally, the appropriate intensity for seedlings or leafy plants like lettuce is 100-300 µmol/m2/s, larger plants can use 400-600 µmol/m2/s, and more mature, robust plants can handle 900 µmol/m2/s. Vigorous growing plants have been shown to make use of 1500 µmol/m2/s and just as reference, sunlight at full exposure, mid-day can get as high as 2000 µmol/m2/s.

Management techniques can affect a plant's light saturation point. For example, doubling the ambient levels of CO2 (atmospheric is 400 ppm) to 800-1000 ppm allows plants to make use of greater light intensity and increase their rate of photosynthesis. The plant can produce more using the supplemental carbon source to fuel photosynthesis and the intense light conditions enable this process. To fully take advantage of CO2 supplementation and the increased light saturation point, the air temperature needs to be higher (relative to the plant species' preferences). The CO2 light intensity, temperature trifecta works in concert to support a faster metabolism and improve plant gains.

Light-emitting diodes (LEDs)

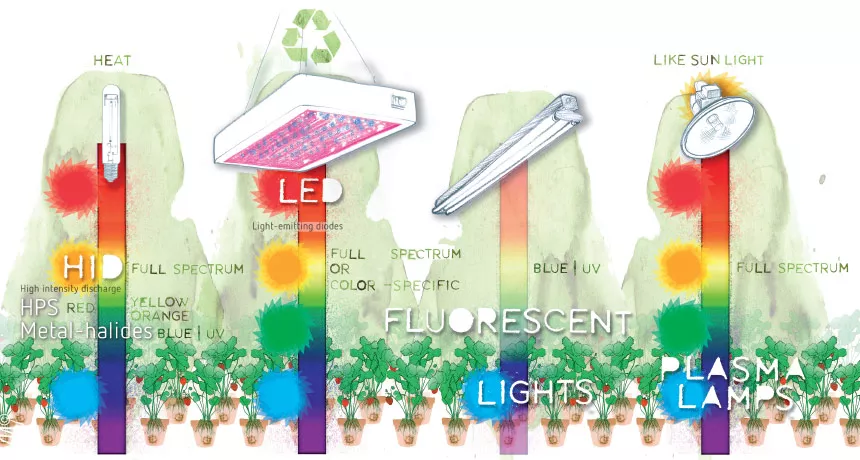

LEDs are semi-conductors that produce light by a process called electro-luminescence. When an electric current flows through an LED, the electrons in the semiconductor recombine with electron holes, and in the process release energy in the form of photons. The color emitted by the photons depends on the semi-conductive material in the LED. Rather than a ballast, a series of resistors are used to deliver the right voltage and current. The power supply can be decreased to dim lights, which give growers the option of varying the level of intensity that LEDs provide.

LEDs are available as full spectrum or as a selection of colors, called narrow spectrum, often being red and blue. With multiple light color options available, LEDs can be used from seed to flowering or to target specific production goals. The appropriate distance from LEDs, whether they are used for seedling development or up to flowering, depends on the wattage of the LED being used.

High intensity discharge (HID) lamps

The color spectrum produced from HIDs depend on the combination of metals sealed in the arc tube. HID lamps produce light by passing electricity through the gaseous metals at high pressure, which heats and then emits light. Given that the gas-metal mixture needs to heat up, these lights require some warm up time before they fully illuminate. The amount of power delivered to the light is regulated by a ballast.

The HID family of lights include metal halide (MH) and high pressure sodium (HPS). HPS lights emit a yellow light, favor the red to yellow/orange spectrum, and contain little blue. This color spectrum is due to the narrower bands of chemicals used to dose the arc tube of the bulb. The color from HPS is well suited for flowering stages. In addition, the arc tube is contained within a larger glass bulb, which filters out most of the UV rays. HPS lights are sometimes used in combination with plasma lamps to give a more uniform spectrum and also provide UV rays.

Metal halides (MH) emit a white light and favor the blue spectrum, making them more favorable for vegetative growth. Ceramic metal halides (CMH) or light emitting ceramic (LEC) lights, produce broad spectrum lighting as well as UV light. Metal halides are sometimes described by their color temperature, measured in Kelvin (K) degrees. Temperatures from 2700-3000K are called warm colors and emit a yellowish light while temperatures over 5000K are considered cool colors and emit a bluish light. In this sense, "warm" lighting actually has a lower temperature than "cooler" light, which has led to some confusion, so be aware.

HIDs generally release a lot of infrared light, felt as heat. To prevent light burn, be sure to adjust the distance between the lights and your plants, depending on plant growth stage and size/wattage of your lamp. The "hand test" is a good way to check if your distance is ok for your plants. Place your hand close to your plants for 30 seconds and if it feels uncomfortably warm for your hand, then it is likely too hot for your plants and you should move your light farther away. A more precise way to verify if you have the correct distance is by using a simple light intensity meter – a worthy investment for better assessing your grow set-up.

Fluorescent lights

Fluorescent lights work by using an electric current to excite mercury vapor, which produces short-wave UV light to then cause a phosphor coating inside the light to glow. Fluorescent tubular bulbs come in a wide variety of lengths from 6 inches to 8 feet and are used widely as interior lighting. The bulbs come in at least 7 different diameters, noted as T4, 5, 8, 9, 12, 17 and so on. A T5 bulb has a diameter of 5/8 of an inch and a T12 bulb has a diameter of 12/8 of an inch, or 1.5 inches. The narrower the bulb, the more efficient and brighter, which is why growers typically use a T5 bulb, with an additional high output (HO) rating. Larger fluorescent bulbs are better suited for interior lighting.

Fluorescent lights emit a bluer toned light and are generally used for seedlings and cuttings, with most growers turning to T5 HO lights. Light emission is strongest near the center of the tube and somewhat less at the ends. Growers have also had success using these lights for fully grown vegetative crops, like lettuce, however these lights are still primarily used for early growth.

Plasma lamps

Plasma lamps generate light by using radio frequency to excite plasma inside a closed bulb. These lamps use noble gases and additional materials such as metal halides, sodium, mercury, or sulfur. A radio frequency generator, called a magnetron is used and, although it may look like it, is not actually a ballast. The light has a spectrum and color temperature similar to that of the sun (around 5900K) which is why the light from plasma lamps is also called artificial sunlight. The light spectrum contains more blue light and also emits UV-B, while UV-C, which is more harmful to plants and people, is filtered out. The safe distance to keep between the light and your plants will vary based on the plants' developmental stage. Plasma lamps tend to use less energy than HID lights and in theory can provide appropriate light till harvest, however, they are generally cost prohibitive for growers to completely rely on. Some growers use plasma lamps as supplemental light in a garden, rather than investing in a full system.

Your illuminated choice

When it comes to lighting, think about what your plants need, your budget, and how you want your garden to shine. Whatever you choose, may your plants bask in the glow and grow like they're in a plant paradise.