Now that we reviewed the basic principles of ventilation, it is time to discuss design concerns for a practical system. The first thing that you need to know is what you are designing for, what influences there will be on the system and how these will change over time. After gathering all the necessary information, the ventilation system can be designed and built along two separate lines: horizontal and vertical ventilation.

Horizontal ventilation

Horizontal ventilation refers to the movement of air inside a defined area. This is the movement that breaks up thermal layering, quickly redistributes air mixtures, and evens out the humidity levels. In this situation, considering plants are being grown in an environment protected from all aspects of nature, the air itself will take on heat as it moves next to heat sources such as lights, fan motors, and outside walls, and give up heat when moving next to areas and things that are cooler, known as sinks.

If the air is allowed to sit without circulation, then as the air becomes energized from the acquisition of heat energy, it will rise and as it loses heat energy, it will sink, and in the process form air layers with different temperatures. This is termed heat stratification and horizontal movement is required to mix these layers and create an even temperature (read also: How air temperature affects plants).

Erasing micro climates

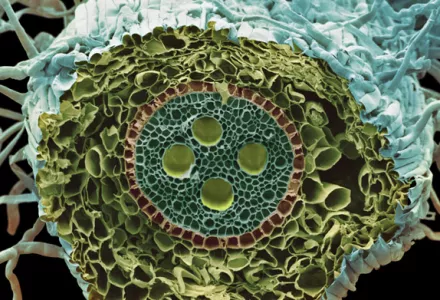

The leaf of the plant has micro pores located around it through which water transpires, driving the movement of water from the roots to the top and moving nutrients internally through the plant in the process. Plants use both Oxygen and Carbon dioxide gas which moves in and out of these pores. It is possible, under calm conditions, to have a backup of these gases trying to move in and out at the same time. These micro-climates (also known as barriers) have to be erased to allow the plant to function at peak efficiency. To increase the efficiency of these gases moving in and out, horizontal air mixing the air in the room erases these micro-climates and helps drive these systems.

Watch our video Optimum day and night temperatures

Requirements

The requirements for Horizontal Air Flow are simple to define but less simple to achieve. The air in the growing zone (the area occupied by the plants) is the target area needing to be moved. Moving the rest of the room is a good idea but air circulation at the ceiling will add to the heat load as most of that air is warmer than the growing area and the floor is liable to harbor more spores tracked in or insects moving in.

Also, how the air will be moved is what determines the pressure on the plants this artificial ‘wind’ will produce. In the end there are really 2 ways to apply this air flow, the first being by the use of air currents produced when removing and replacing the air in the room and the other through a separate, dedicated device such as a smaller fan or High Efficiency Horizontal Fans that are designed to create a small vortex effect in the target zone.

Speed of air movement and distribution

When using both a horizontal system and a vertical or exhausting system, there can be a cumulative air pressure/ speed effect that must be monitored. The ideal speed level should produce a gentle moving of all leaves in the grow zone. This will insure proper mixing of the air and not uproot or damage any of the plants.

Where possible use 2 wall fans in smaller areas that are placed at the level of the plants and face in different directions which will create a rotation in the air mass, This allows for the best air distribution in the grow zone. In bigger areas, high efficiency horizontal fans create a high force but smaller volume so that, while being very effective at creating that circulation in the area, it is not large enough to directly impact the plants and are usually placed so that the flow from the fan is directly above the top of the plants.

A stronger vortex just above the plant tops creates the desired gentle movement in the leaf zone. This type of action is really impossible with the vertical systems which also must be designed to move all the air in the room or area not just that located in the growth zone.

Vertical Ventilation

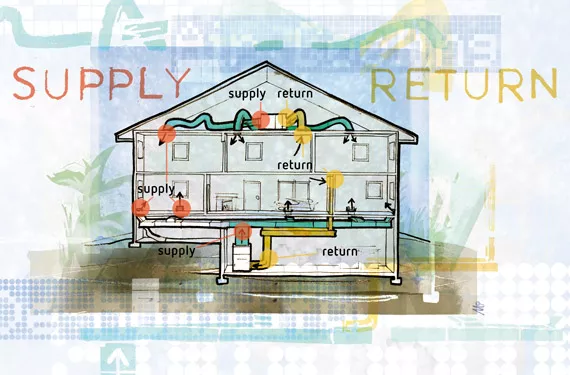

Vertical ventilation is a term used strictly in this case to imply air that is moved out of the area and treated to be returned or replaced by air from another location. Unless the designed system supplies and exhausts the air from the floor and ceiling, all air flow is horizontal, so the implication in this system is the air is moved across multilevels and not across the same level. Air in an area used for plant production must be changed out on a regular basis to avoid many issues, such as disease and cross contamination.

Exchanging the air adjusts the temperature, changes the humidity, and replaces the gases that can be used up in sealed situations, for example Carbon dioxide (read: Carbon dioxide's role and management in the growing environment). While horizontal ventilation will mix the air and thus moderate temperature, humidity and gas ratios by diffusing the changes across the entire room atmosphere, it will not remove or add heat, humidity or replace gases that have been used up. Air exchange is the only real answer.

Open and closed systems

There are 2 ways to view the Vertical system, either open, meaning that either the system draws air from a different area which replaces the air in the target area, or closed, meaning the actual air never leaves the area and is treated in place. The treatment of cooling or heating, humidifying or dehumidifying and of gas replacement for the air is important in both systems but required in a closed system. Depending on the need of the controls for the environment faced by the growing facility and the needs of the crops produced, the air movement through exchange, in either an open or closed system would determine the exact design of the system.

Closed systems

A closed system would be used in situations where contamination, biological or environmental such as Ozone or other industrial pollutants, needed to be avoided; contact between the environment of the interior and exterior is maintained separately. The area air is removed, treated and returned to the area.

Open systems

An open system pulls its exchange air from an exterior source such as a controlled room or the outside. It can be treated or used directly to affect change in temperature, humidity, and gas content, or treated to cool, heat, humidify, or dehumidify. This air is then pulled through the area to remove the old air, at a rate of speed that can make a difference. The entire time it is pulling this air out of the room, the factors that caused the undesirable change in temperature or humidity continue to occur.

Designing the system

The designer needs to understand what the heat gain or loss is for the area, usually figured in BTU’s or British Thermal Units. Then what BTU’s are added or removed to hold or affect temperature and what is the design parameters based on all factors including what the crop needs and what environment the area’s system will be working under. Once this is known then the designer builds a system that will be able to hold a given set of values in temperature and/ or humidity based on the difference between the average worst case and where the condition needs to be.

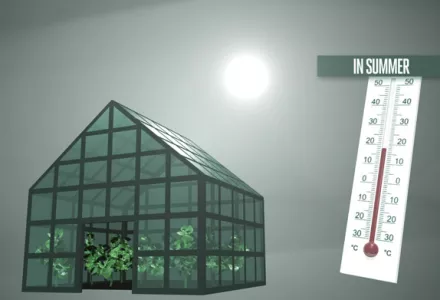

Temperature

If the indoor temperature, for example, under light and in the summer will get to 120o F (49o C) and the maximum the plant should be held at is 90o F (32o C) then the system must be able to affect change for a 30o F (17o C) differential. Heating is the same and humidity is as well although figured differently.

Gas ratios

Gas ratios in an open system are not really an issue as the ratios will, or should always match what is available outdoors which is always sufficient. In a closed system Carbon dioxide supplementation is required during the photosynthetic period as the existing CO2 will be used up in a very short amount of time, so fast as to begin to slow down metabolic processes within a couple hours. Oxygen, on the other hand, while used by the plant at normal life levels, is released in heavy enough concentrations during the fixing of the Carbon in the CO2, as to supply all that is needed. Looking for more info about carbon dioxide applications in indoor growing? Read Carbon dioxide (CO2) applications in indoor growing.

Which components?

The exact need of the system will determine what components are parts of the system. In a closed system, the ability of the environment will determine if an evaporative cooling system would work well enough or if a HVAC (Heating, Ventilation, and Air Conditioning) unit will be required. The need to move a certain amount of air for these changes will determine the size of the duct work and the fans required. Open systems will work by directly pulling the air, in whatever state it is in, into the target area. If the air needs cooling and humidifying, an evaporative cooling system might be an answer (known as Swamp Chillers, in some locations, and which can also be used in a closed system).

The calculations for these type systems should be done and sized correctly to insure that a system is both functional and cost effective. Everything that would affect a system must be known which includes restrictions such as bends in duct work and filters used. It is also usually critical to use fans on both the exhaust and input sides to both insure good air movement as well as balancing the pressure in the room.

Controls

Controls for the automation of these systems are also a big concern and cannot be forgotten in the rush to finalize a system. Unless the grower or a grower’s representative can afford to watch a thermometer, a hygrometer, and a CO2 monitor all day and night, 24 hours a day and 7 days a week for months, there will have to be an allowance for a device to control the operations of the Vertical ventilation based system, open or closed. The horizontal system tends to remain active all the time so a controller is not necessary other than an ON/ OFF switch.

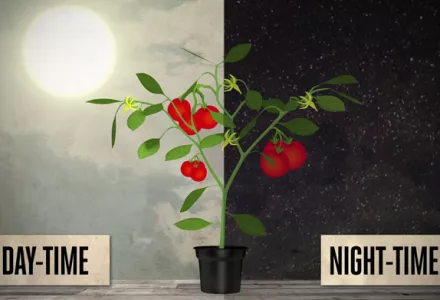

Remote monitoring and control devices are available. At the simplest, a system will need a thermostat that controls the on/ off operation of a system to control cooling. There will also be the need for one that operates a heat system that may be tied into the vent system. In addition, a humidistat that operates the vent system when the humidity gets above a certain selected level also helps with environmental regulation. It might also be desirable to be able to dial in different values for a night cycle, especially in temperature. Considering how air temperature affects plants, some systems, especially at certain times of the year, might require cooling during the daylight and heating during dark hours, especially in greenhouse environments.

In closed systems, where certain gas products are released to supplement or raise ambient levels, such as CO2, a gas monitor is also a good idea, especially one that might trigger alarms should the regulation of that gas fail. Adding CO2, while a positive thing for the crop, can be costly and provide diminishing returns once too much is used, and dangerous to employees and growers if it gets too high when people are present. An added value is achieved when the CO2 controller can change the ventilation pattern so that the gas is not exhausted as it is put in or at a certain time after injection, by a system fighting to hold a certain temperature or humidity.

Keep it simple

Each environmental control has to work together to be of value or effective for the overall cropping purposes. Also, the less complex controls can be used, the less chance for error or failure. Temperature, humidity and gas injection is controlled by the use of set points so that, while a grower requests say a 72oF temperature for cooling, the system will turn on a few degrees warmer and run till it is a few degrees cooler. This allows the system to work more efficiently and strict control is not needed or the system will run all the time clicking on and off within a single degree or less, of change.

Ventilation is not the easiest part of the equation for growing, however environmental control is one of the most important parts of growing. It cannot be neglected in the rush to produce or in the overall design of the grow facility. Proper care must be taken from the design to the installation to insure function and therfore success.